We can support you with a wide variety of experiences from Large-Facilities to Small cooling towers of offices such a Heavy Industrial & Utility Applications, Factory Plants, Power Plants , Schools, Hotels, Shopping Malls, HOT SPAs, Restaurants, office buildings, Chemical Industry and other Applications.

|

|

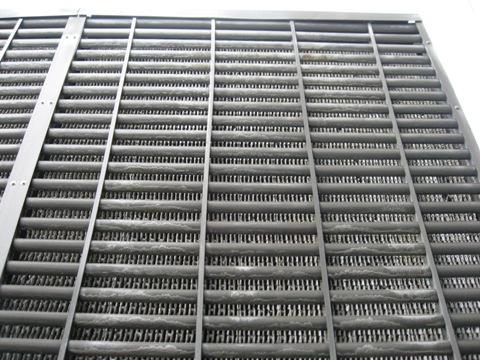

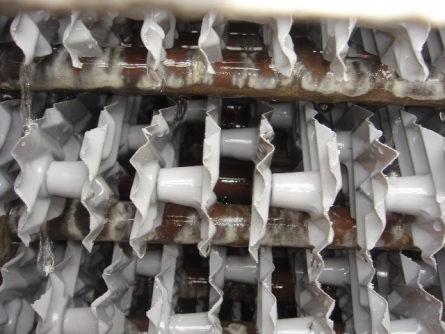

| 590RT*2 cooling towers that fouled with a large quantity of Ca+Si scale . They did not have enough cooling capabilities of the towers. The client had used Mixed Conventional Organic Chemical that one of Major Water Chemical company suppied for past 10 years, but it NO effective. The client make a contact with us to ask removing Scale, Bacteria, Algae on Cooling Tower, Heat Exchangers, Pumps, Pipes to recover the original cooling capability & to save energy cost. First seconds movie , CALFA BAS + CALFA SAT installed to the cooling towers , and 28 days later. A large QTY of scale became soft, and easy to remove by Hand. After that, they got more soft, and fell down to inside of towers naturally day by day. (Fell down naturally If parts where are always circulated water flowing,) so, Clean Up of towers were necessary. (Outside of the fillers are not only a splash, but became softer than do nothing) Finally, A large QTY of Scale fell down in Towers after 49 days CALFA BAS + CALFA SAT Installed, and cleaned up. |

|

|

|

With Organic Conventional Anti-Scale Chemicals + General Bactericide |

With CALFA BAS + CALFA SAT |

Background Information: We put 3 cooling towers to trial. 1 was a co-generation system and others were Air Conditioning systems. The cooling towers had used organic compound chemicals by 2006. Then, they tried to do "RE-USE" the water for supplying flowers or plants by using sprinklers periodically. So, they stopped using organic compound chemicals in 2007, because organic compound chemicals are not suitable for any plants in the garden ,or human bodies also. After stopped using them, they spent too much water for "supply and waste" to prevent fouling scale, At last, plenty of scales were fouled on the surface of heat exchangers. They have started CALFA BAS in 2008.

Aug. 2008 without "CALFA BAS" |

Aug. 2008 with "CALFA BAS" |

|||||||||

|

|

|||||||||

Before Installed |

||||||||||

|

|

|||||||||

1 Month later |

1 Month later |

|||||||||

|

|

|||||||||

2 Months later |

2 Months later |

|||||||||

The result of trial with "CALFA BAS" |

||||||||||

|

||||||||||

|

||||||||||

|

|

||

May, 13th 2008 (before Install CALFA BAS) |

May, 13th 2008 (before Install CALFA BAS) |

||

|

|

||

June, 10th 2008 |

June, 10th 2008 |

||

|

|

||

October, 10th 2008 |

October, 10th 2008 |

||

|

|

||

November, 18th 2008 |

November, 18th 2008 |

||

|

|

||

Removed Scale (The cleaning Day) |

Removed Scale (The cleaning Day) |

||

| Removed Scale Formation

|

|

|

|

Removed Scale (The cleaning Day) |

Removed Scale (The cleaning Day) |

üyFrom 125RT Closed Type of Cooling Towerüz |

üyFrom 125RT Closed Type of "SUB" Cooling Towerüz |

The cooling system operates just for air conditioners during summer season. Also, it's located near a duct of kitchen of restaurants. Therefore, The water in cooling tower has much Nitrogen, and Microscopic Organism. Thus, We used both "CALFA BAS" and "CALFA SAT". If it seems that the Scale is formed by Large Silica, it's easy to resolve the problem such as this case with the superior effectiveness of "CALFA BAS". In fact, the removed scale was about five times as much as the above picture. (The picture QTY is only 1/5). This is a typical case which succeeded remarkable energy and water saving.

|

The cooling system operates just for air conditioners during summer season. Also, The building which the cooling tower is set located on main streets congested with traffic and always strongly windy. It should have much SoX & NoX, and Microscopic Organism. Thus, we both used "CALFA BAS" and "CALFA SAT" . It seemed that the Scale was formed by Silica & Calcium Mixed . This cooling tower has been used as a SUB unit of cooling system. However, Scale was formed as much quantity as like above picture, in only 1 year. Excess "Energy" and "Cost" did not need to be used if CALFA BAS was installed earlier.

|

.png)

Background Information: The hotel is one of the big famous hotel in Japan. There were 2 cooling towers which have terrible bad conditions, FILLS had been fouled by plenty of Scale, Slime, Bacteria, and Algae, because they never been maintained for over 20 years after the cooling towers were set up, and fills were transformed due to the too much weight of that (Scale, Slime, Bacteria, Algae). Of course, since a wind does not enter at all, it does not get cold. Fans continued turning for 24 hours, It spent a lot of excess energy as a result. It has changed freezers to new one but the budget of changing fills of cooling towers was far exceeded. Thus, Our trial was to recover the cooling performance of them using CALFA BAS & CALFA SAT. Besides, We had another 2 problem to do that. It was "Limited Time". and "Flow Rate". The client would liked us to do with tentative pumps which made recirculating water from the collection basin (bottom) to distribution basin (upper) using only 20% of the water that compare with usual volume of the water. So, Our Mission was "To recover the cooling performance using 20% of the water within only 1 month. It was the most difficult trial terms, and a big challenge for us.

|

|

|

Feb, 25th 2009 (before Install CALFA BAS & CALFA SAT) |

Mar, 25th 2009 (28 days later) |

|

|

||

Feb, 25th 2009 (before Install CALFA BAS & CALFA SAT) Scale & Silme & Algae |

Mar, 25th 2009 (28 days later) Removed Silme & Algae (90% of Scale removed) |

||

|

|

||

Feb, 25th 2009 (before Install CALFA BAS & CALFA SAT) Scale & Silme & Algae |

Mar, 25th 2009 (28days later) Removed Silme & Algae (90% of Scale removed) |

||

| BEFORE INSTALLED (Feb, 25th 2009) | |||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||

| CALFA BAS & CALFA SAT INSTALLED | |||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

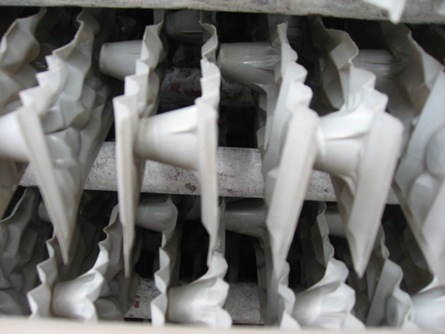

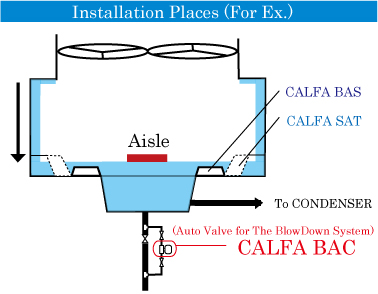

Standard Insatllation Places |

Installing CALFA SAT |

|

|

|

One of Major Organic water chemicals manufacture Anti Scaling chemical + Anti Corrosion chemical ü{ Bactericide üiaround 10 years usedüj |

Changed to CALFA BAS + CALFA SAT |

|

Dry Air could not go into the tower, to say nothing of save an |

ü@ | This is the first time to clean up in the cooling tower after changed to CALFA BAS + CALFA SAT. A large QTY of scale (Ca+Si) which fouled the cooling tower for 10 years removed from it. then, the client does not need Excess Energy Cost, changing Plastic Fillings cost, and worring about STOP by High Plreasure cut. |

CALFA BAS + CALFA SAT Installation Seen |